What is LPG Vaporizer and how does it work? ENGGMECH

Most Efficient Manufactured with best practices to meet

the desired outcome

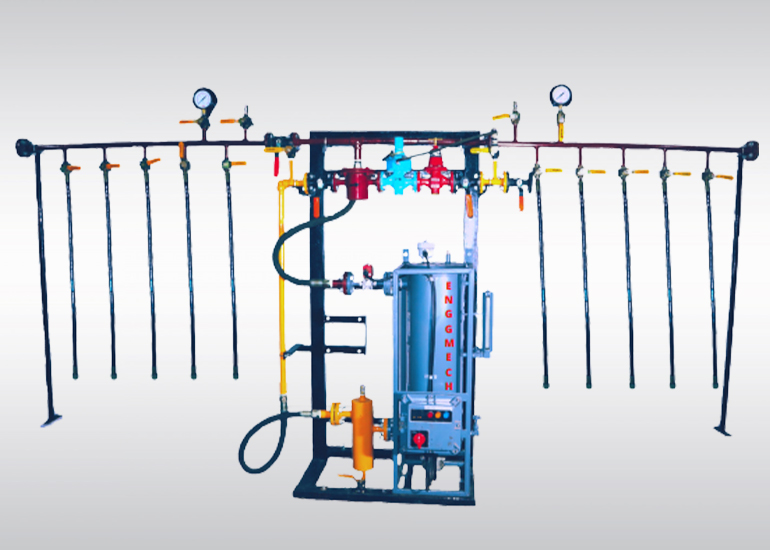

Factory Made System: Our system comprises of Best in

class “LPG/Propane Vaporizer” and Liquid Off take

Manifold system, completely manufactured with state of

art Manufacturing Process with the Latest Technology.

Easiest to Install: Wall mounted, ready to install and use

within minutes.

Readily Available: High on stock inventory with express

delivery PAN India

Customisable: Choose the number of vaporisers and

Manifolds systems as per your requirement

Key Features

- Range starting from 50 Kg/hr to 150 Kg/hr

- The system comes in a ready-to-use state

- Plug and play model makes it easy to install and use within minutes

- Digital panel with digital display

- Top-rated safety components

- Custom models and sizes available

- PRV Station

- Flame proof equipment

- Zero maintenance cost

- Very convenient to handle

- No residual loss of your fuel

- Comes with best in class LPG Vaporiser

- Strainer provided at manifold outlet

Technical Specifications

| Model | Vaporiser Model | Class | Inlet/Outlet(mm) | Monidfold System | |||

| CFT-50 | ULTIMO | Techno PLUS | DN25 | suitable for 35/47.5kg | suitable for 425kg | ||

| CFT-100 | ULTIMO | Techno PLUS | DN25 | 5 X 2 | 10 X 2 | 20 X 2 | 2X2 /2X3 /2X4 /2X5 |

| CFT-150 | ULTIMO | Techno PLUS | DN25 | 5 X 2 | 10 X 2 | 20 X 2 | 2X2 /2X3 /2X4 /2X5 |

| CFT-200 | ULTIMO | Techno PLUS | DN25 | 5 X 2 | 10 X 2 | 20 X 2 | 2X2 /2X3 /2X4 /2X5 |

| CFT-300 | ULTIMO | Techno PLUS | DN25 | 5 X 2 | 10 X 2 | 20 X 2 | 2X2 /2X3 /2X4 /2X5 |

An LPG (liquefied petroleum gas) vaporizer is a device used to convert liquid propane or butane into a gaseous form that can be used as fuel for various applications, such as heating, cooking, and industrial processes. LPG is commonly stored and transported in a liquid state under pressure, but it needs to be vaporized before it can be used in gas appliances.

The basic principle of an LPG vaporizer involves the application of heat to the liquid propane or butane, causing it to change from a liquid to a gaseous state. There are different types of LPG vaporizers, but some common ones include:

Water Bath Vaporizers: These vaporizers use a heated water bath to transfer heat to the LPG. The LPG flows through a coil or a series of pipes immersed in a hot water bath. As the liquid comes into contact with the hot surface, it absorbs heat and vaporizes into a gas.

Shell and Tube Vaporizers: In this design, LPG flows through tubes, and hot water or another heating medium surrounds the tubes in a shell. Heat is transferred from the surrounding medium to the LPG through the tube walls, causing vaporization.

Direct-Fired Vaporizers: In this type, a burner directly heats the LPG. The liquid passes through a chamber where it comes into contact with an open flame or a heated surface, causing it to vaporize.

The choice of vaporizer depends on factors such as the required vaporization capacity, the specific application, and environmental considerations. It's crucial to ensure that the vaporizer is designed and operated safely to prevent accidents, as LPG is flammable. Additionally, some vaporizers incorporate safety features such as pressure relief valves and temperature controls to maintain optimal operating conditions. Regular maintenance and inspection are essential to ensure the proper functioning of the LPG vaporizer.